Geothermal power (from the Greek roots geo, meaning earth, and thermos, meaning heat) is power extracted from heat stored in the earth. This geothermal energy originates from the original formation of the planet, from radioactive decay of minerals, and from solar energy absorbed at the surface. It has been used for bathing since Paleolithic times and for space heating since ancient Roman times, but is now better known for generating electricity. Worldwide, geothermal plants have the capacity to generate about 10 gigawatts of electricity as of 2007, and in practice supply 0.3% of global electricity demand. An additional 28 gigawatts of direct geothermal heating capacity is installed for district heating, space heating, spas, industrial processes, desalination and agricultural applications.

Geothermal power is cost effective, reliable, sustainable, and environmentally friendly, but has historically been limited to areas near tectonic plate boundaries. Recent technological advances have dramatically expanded the range and size of viable resources, especially for applications such as home heating, opening a potential for widespread exploitation. Geothermal wells release greenhouse gases trapped deep within the earth, but these emissions are much lower per energy unit than those of fossil fuels. As a result, geothermal power has the potential to help mitigate global warming if widely deployed in place of fossil fuels.

The Earth's geothermal resources are theoretically more than adequate to supply humanity's energy needs, but only a very small fraction of it may be profitably exploited. Drilling and exploration for deep resources costs tens of millions of dollars, and success is not guaranteed. Forecasts for the future penetration of geothermal power depend on assumptions about technology growth, the price of energy, subsidies, and interest rates.

Electricity

Geothermal electric power plants have been limited to the edges of

tectonic plates until recently.

Twenty-four countries generated a total of 56,786 gigawatt-hours (GW·h) (204 PJ) of electricity from geothermal power in 2005, accounting for 0.3% of worldwide electricity consumption. Output is growing by 3% annually, because of a growing number of plants and improvements in their

capacity factors. Because geothermal power does not rely on variable sources of energy, unlike, for example, wind or solar, its capacity factor can be quite large—up to 96% has been demonstrated.

[1] The global average was 73% in 2005. The global installed capacity was 10

gigawatts (GW) in 2007.

[2]

The largest group of geothermal

power plants in the world is located at

The Geysers, a geothermal field in

California,

United States.

[3] As of 2004, five countries (

El Salvador,

Kenya,

the Philippines,

Iceland, and

Costa Rica) generate more than 15% of their electricity from geothermal sources.

[2]

Geothermal electric plants have until recently been built exclusively on the edges of tectonic plates where high temperature geothermal resources are available near the surface. The development of

binary cycle power plants and improvements in drilling and extraction technology may enable

enhanced geothermal systems over a much greater geographical range.

[4] Demonstration projects are operational in

Landau-Pfalz, Germany, and

Soultz-sous-Forêts, France, while an earlier effort in

Basel, Switzerland was shut down after it triggered earthquakes. Other demonstration projects are under construction in

Australia, the

United Kingdom, and the

United States of America.

[5]

Direct application

Approximately 70 countries made direct use of a total of 270

petajoules (PJ) of

geothermal heating in 2004. More than half of this energy was used for space heating, and another third for heated pools. The remainder supported industrial and agricultural applications. The global installed capacity was 28 GW, but capacity factors tend to be low (30% on average) since heat is mostly needed in the winter. The above figures are dominated by 88 PJ of space heating extracted by an estimated 1.3 million

geothermal heat pumps with a total capacity of 15 GW.

[2] Heat pumps are the fastest-growing means of exploiting geothermal energy, with a global annual growth rate of 30% in energy production.

[6] Most of these new heat pumps are being installed for home heating.

Direct heating in all its forms is far more efficient than electricity generation and places less demanding temperature requirements on the heat resource. Heat may come from

co-generation with a geothermal electrical plant or from smaller wells or heat exchangers buried in shallow ground. As a result, geothermal heating is economic over a much greater geographical range than geothermal electricity. Where natural

hot springs are available, the heated water can be piped directly into

radiators. If the ground is hot but dry,

earth tubes or

downhole heat exchangers can collect the heat. But even in areas where the ground is colder than room temperature, heat can still be extracted with a geothermal heat pump more cost-effectively and cleanly than it can be produced by conventional furnaces.

[7] These devices draw on much shallower and colder resources than traditional geothermal techniques, and they frequently combine a variety of other functions, including

air conditioning,

seasonal energy storage,

solar energy collection, and electric heating. Geothermal heat pumps can be used for space heating essentially anywhere in the world.

Geothermal heat supports many applications.

District heating applications use networks of piped hot water to heat buildings in whole communities. In

Reykjavík, Iceland, spent water from the district heating system is piped below the pavement and sidewalks to melt snow.

[8] Geothermal desalination has been demonstrated.

Environmental impact

Krafla Geothermal Station in northeast Iceland

Fluids drawn from the deep earth carry a mixture of gases, notably

carbon dioxide (

CO2),

hydrogen sulfide (

H2S),

methane (

CH4) and

ammonia (

NH3). These pollutants contribute to

global warming,

acid rain, and noxious smells if released. Existing geothermal electric plants emit an average of 122 kg of

CO2 per megawatt-hour (MW·h) of electricity, a small fraction of the

emission intensity of conventional fossil fuel plants.

[9] Plants that experience high levels of acids and volatile chemicals are usually equipped with emission-control systems to reduce the exhaust. Geothermal plants could theoretically inject these gases back into the earth, as a form of

carbon capture and storage.

In addition to dissolved gases, hot water from geothermal sources may hold in solution trace amounts of toxic chemicals such as mercury, arsenic, boron, antimony, and salt.

[10] These chemicals come out of solution as the water cools, and can cause environmental damage if released. The modern practice of injecting spent geothermal fluids back into the Earth to stimulate production has the side benefit of reducing this environmental risk.

Direct geothermal heating systems will contain pumps and compressors, and the electricity they consume may come from a polluting source. This

parasitic load is normally a fraction of the heat output, so it is always less polluting than electric heating. However, if the electricity is produced by burning fuels, then the net pollution of geothermal heating may be comparable to directly burning the fuel for heat. For example, a geothermal heat pump powered by electricity from a

combined cycle natural gas plant would produce about as much pollution as a natural gas

condensing furnace of the same size.

[7] Therefore the environmental value of direct geothermal heating applications is highly dependent on the emissions intensity of the neighboring electric grid.

Plant construction can adversely affect land stability. Subsidence has occurred in the

Wairakei field in New Zealand

[11] and in

Staufen im Breisgau, Germany.

[12] Enhanced geothermal systems can trigger

earthquakes as part of

hydraulic fracturing. The project in

Basel,

Switzerland was suspended because more than 10,000 seismic events measuring up to 3.4 on the

Richter Scale occurred over the first 6 days of water injection.

[13]

Geothermal has minimal land and freshwater requirements. Geothermal plants use 3.5 square kilometres per gigawatt of electrical production (not capacity) versus 32 and 12 square kilometres for coal facilities and wind farms respectively.

[11] They use 20 litres of freshwater per MW·h versus over 1000 litres per MW·h for nuclear, coal, or oil.

[11]

Economics

Geothermal power requires no fuel, and is therefore immune to fuel cost fluctuations, but capital costs tend to be high. Drilling accounts for over half the costs, and exploration of deep resources entails significant risks. A typical well doublet in Nevada can support 4.5

megawatts (MW) of electricity generation and costs about $10 million to drill, with a 20% failure rate.

[14] In total, electrical plant construction and well drilling cost about 2-5 million € per MW of electrical capacity, while the

levelised energy cost is 0.04-0.10 € per kW·h.

[15] Enhanced geothermal systems tend to be on the high side of these ranges, with capital costs above $4 million per MW and levelized costs above $0.054 per kW·h in 2007.

[16] Direct heating applications can use much shallower wells with lower temperatures, so smaller systems with lower costs and risks are feasible. Residential geothermal heat pumps with a capacity of 10 kilowatt (kW) are routinely installed for around 1–3 thousand dollars per kilowatt. District heating systems may benefit from economies of scale if demand is geographically dense, as in cities, but otherwise piping installation will dominate capital costs. The capital cost of one such district heating system in Bavaria was estimated at somewhat over 1 million € per MW.

[17] Direct systems of any size are much simpler than electric generators and have lower maintenance costs per kW·h, but they must consume electricity to run pumps and compressors. Some governments subsidize geothermal power, either for electricity generation or direct applications.

Geothermal power is highly scalable: a large geothermal plant can power entire cities while a smaller power plant can supply a rural village.

[18]

Chevron Corporation is the world's largest private producer of geothermal electricity.

[19] The most developed geothermal field is

the Geysers in California.

Resources

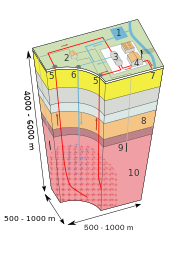

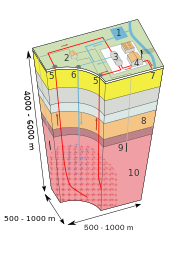

Enhanced geothermal system 1:Reservoir 2:Pump house 3:Heat exchanger 4:Turbine hall 5:Production well 6:Injection well 7:Hot water to district heating 8:Porous sediments 9:Observation well 10:Crystalline bedrock

The Earth's internal heat naturally flows to the surface by conduction at a rate of 44.2

terawatts, (TW,)

[20] and is replenished by radioactive decay of minerals at a rate of 30 TW.

[21] These power rates are more than double humanity’s current energy consumption from all primary sources, but most of it is not recoverable. In addition to heat emanating from deep within the Earth, the top ten metres of the ground accumulates solar energy (warms up) during the summer, and releases that energy (cools down) during the winter.

Beneath the seasonal variations, the

geothermal gradient of temperatures through the crust is 25–30 °C per

kilometre (km) of depth in most of the world. The conductive heat

flux is approximately 0.1 MW/km

2 on average. These values are much higher near tectonic plate boundaries where the crust is thinner. They may be further augmented by fluid circulation, either through

magma conduits,

hot springs,

hydrothermal circulation or a combination of these.

A geothermal heat pump can extract enough heat from shallow ground anywhere in the world to provide home heating, but industrial applications need the higher temperatures of deep resources.

[11] The thermal efficiency and profitability of electricity generation is particularly sensitive to temperature. The more demanding applications receive the greatest benefit from a high natural heat flux, ideally from using a

hot spring. If no hot spring is available, the next best option is to drill a well into a hot

aquifer. If no adequate aquifer is available, an artificial one may be built by injecting water to

hydraulically fracture the bedrock. This last approach is called

hot dry rock geothermal energy in Europe, or

enhanced geothermal systems in North America. Much greater potential may be available from this approach than from conventional tapping of natural aquifers.

[4]

Estimates of the electricity generating potential of geothermal energy vary from 35 to 2000 GW depending on the scale of investments.

[2] Upper estimates of geothermal resources assume enhanced geothermal wells as deep as 10 kilometres (6 mi), whereas existing geothermal wells are rarely more than 3 kilometres (2 mi) deep.

[2] Drilling at this depth is now possible in the petroleum industry, although it is an expensive process. The deepest research well in the world, the

Kola superdeep borehole, is 12 kilometres (7 mi) deep.

[22] This record has recently been imitated by commercial oil wells, such as

Exxon's Z-12 well in the Chayvo field,

Sakhalin.

[23]

Sustainability

Geothermal power is considered to be

sustainable because the heat extraction is small compared to the Earth's heat content. The Earth has an internal heat content of

1031 joules (3·10

15 TW·hr).

[2] About 20% of this is residual heat from

planetary accretion, and the remainder is attributed to higher radioactive decay rates that existed in the past.

[24] Natural heat flows are not in equilibrium, and the planet is slowly cooling down on geologic timescales. Human extraction taps a minute fraction of the natural outflow, often without accelerating it.

Even though geothermal power is globally sustainable, extraction must still be monitored to avoid local depletion.

[21] Over the course of decades, individual wells draw down local temperatures and water levels until a new equilibrium is reached with natural flows. The three oldest sites, at Larderello, Wairakei, and the Geysers have all reduced production from their peaks because of local depletion. Heat and water, in uncertain proportions, were extracted faster than they were replenished. If production is reduced and water is reinjected, these wells could theoretically recover their full potential. Such mitigation strategies have already been implemented at some sites. The long-term sustainability of geothermal energy has been demonstrated at the Lardarello field in Italy since 1913, at the Wairakei field in New Zealand since 1958,

[25] and at The Geysers field in California since 1960.

[26]

History

The oldest known pool fed by a hot spring, built in the Qin dynasty in the 3rd century BC.

have been used for bathing at least since

paleolithic times.

[27] The oldest known spa is a stone pool on

China’s

Lisan mountain built in the

Qin dynasty in the 3rd century BC, at the same site where the

Huaqing Chi palace was later built. In the first century AD, Romans conquered

Aquae Sulis and used the hot springs there to feed

public baths and

underfloor heating. The admission fees for these baths probably represent the first commercial use of geothermal power. The world's oldest geothermal district heating system in

Chaudes-Aigues,

France, has been operating since the 14th century.

[11] The earliest industrial exploitation began in 1827 with the use of geyser steam to extract

boric acid from

volcanic mud in

Larderello, Italy.

In 1892, America's first district heating system in

Boise, Idaho was powered directly by geothermal energy, and was copied in

Klamath Falls, Oregon in 1900. A deep geothermal well was used to heat greenhouses in Boise in 1926, and geysers were used to heat greenhouses in Iceland and Tuscany at about the same time.

[28] Charlie Lieb developed the first

downhole heat exchanger in 1930 to heat his house. Steam and hot water from geysers began heating homes in Iceland starting in 1943.

Global geothermal electric capacity. Upper red line is installed capacity;

[15] lower green line is realized production.

[2]

In the 20th century, demand for electricity led to the consideration of geothermal power as a generating source. Prince

Piero Ginori Conti tested the first geothermal power generator on 4 July 1904, at the same Larderello dry steam field where geothermal acid extraction began. It successfully lit four light bulbs.

[29] Later, in 1911, the world's first commercial geothermal power plant was built there. It was the world's only industrial producer of geothermal electricity until New Zealand built a plant in 1958.

By this time,

Lord Kelvin had already invented the

heat pump in 1852, and

Heinrich Zoelly had patented the idea of using it to draw heat from the ground in 1912.

[30] But it was not until the late 1940s that the geothermal heat pump was successfully implemented. The earliest one was probably Robert C. Webber's home-made 2.2 kW direct-exchange system, but sources disagree as to the exact timeline of his invention.

[30] J. Donald Kroeker designed the first commercial geothermal heat pump to heat the

Commonwealth Building (Portland, Oregon) and demonstrated it in 1946.

[31][32] Professor Carl Nielsen of

Ohio State University built the first residential open loop version in his home in 1948.

[33] The technology became popular in Sweden as a result of the

1973 oil crisis, and has been growing slowly in worldwide acceptance since then. The 1979 development of

polybutylene pipe greatly augmented the heat pump’s economic viability.

[31]

In 1960,

Pacific Gas and Electric began operation of the first successful geothermal electric power plant in the United States at The Geysers in California.

[34] The original turbine lasted for more than 30 years and produced 11

MW net power.

[35]

The

binary cycle power plant was first demonstrated in 1967 in Russia and later introduced to the USA in 1981.

[34] This technology allows the generation of electricity from much lower temperature resources than was previously viable. In 2006, a binary cycle plant in Chena Hot Springs, Alaska, came on-line, producing electricity from a record low fluid temperature of 57 °C.

[36]